Hello, and today I will talk about how I made a working heat shield with every day materials. Are space agency name is Big Boy’s space agency. We had vey strict rules for designing are heat shield. It had to be 1 cm or less and it had to weigh 42 grams or less and you could only use a limited amount of supply’s.

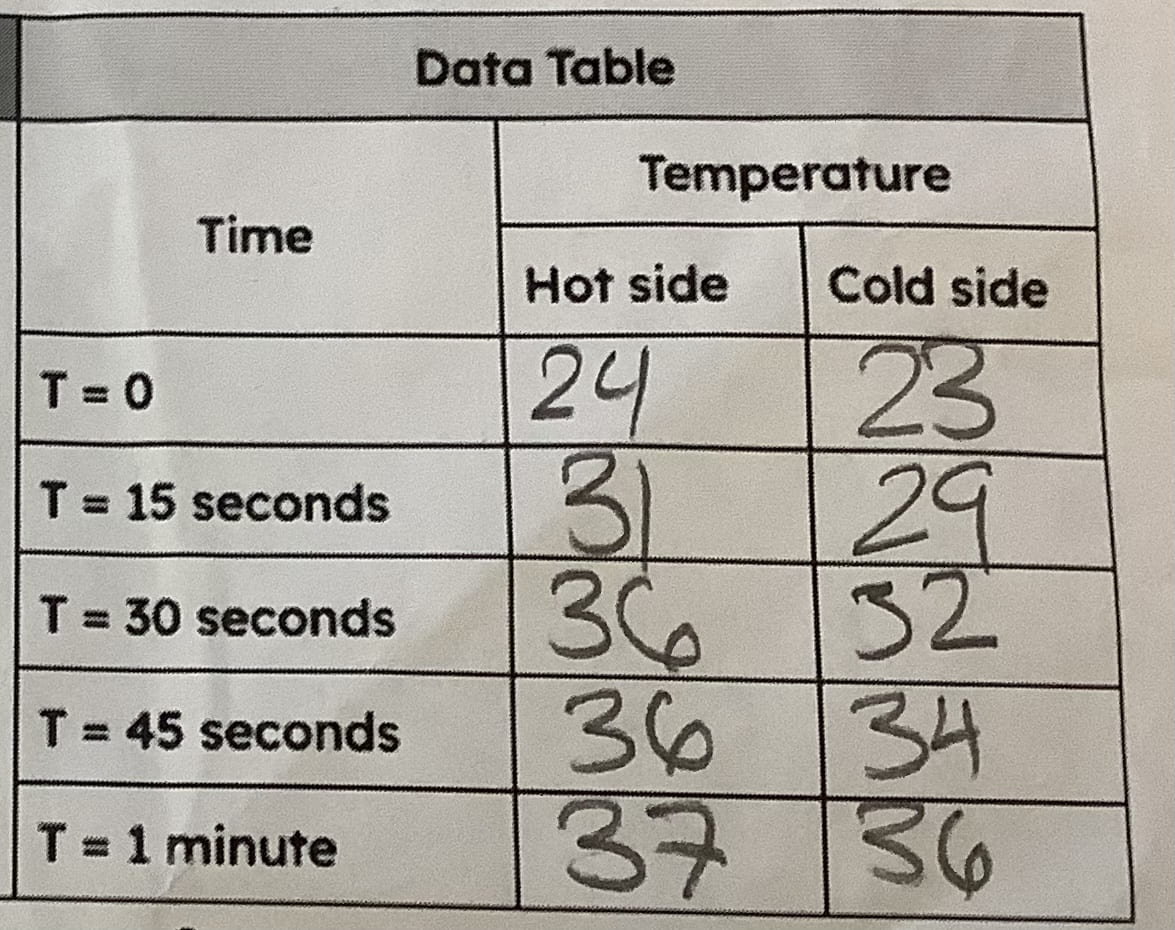

My heat shield weighed 21 grams and was less than 1 cm. It was made out of tin foil, metal lathe, lasagna, Duck tape and a sponge. How we decided to use and order these materials is through tests. The first test that we ran was with tin foil and metal lathe. we use a heat gun that got up to 572 degrees Fahrenheit. In the photo you can see the hot and cold side temperature for a minute. As you can see these materials were very good.

This test was about finding good materials that will protect the front of the heat shield. These materials are good conductors.

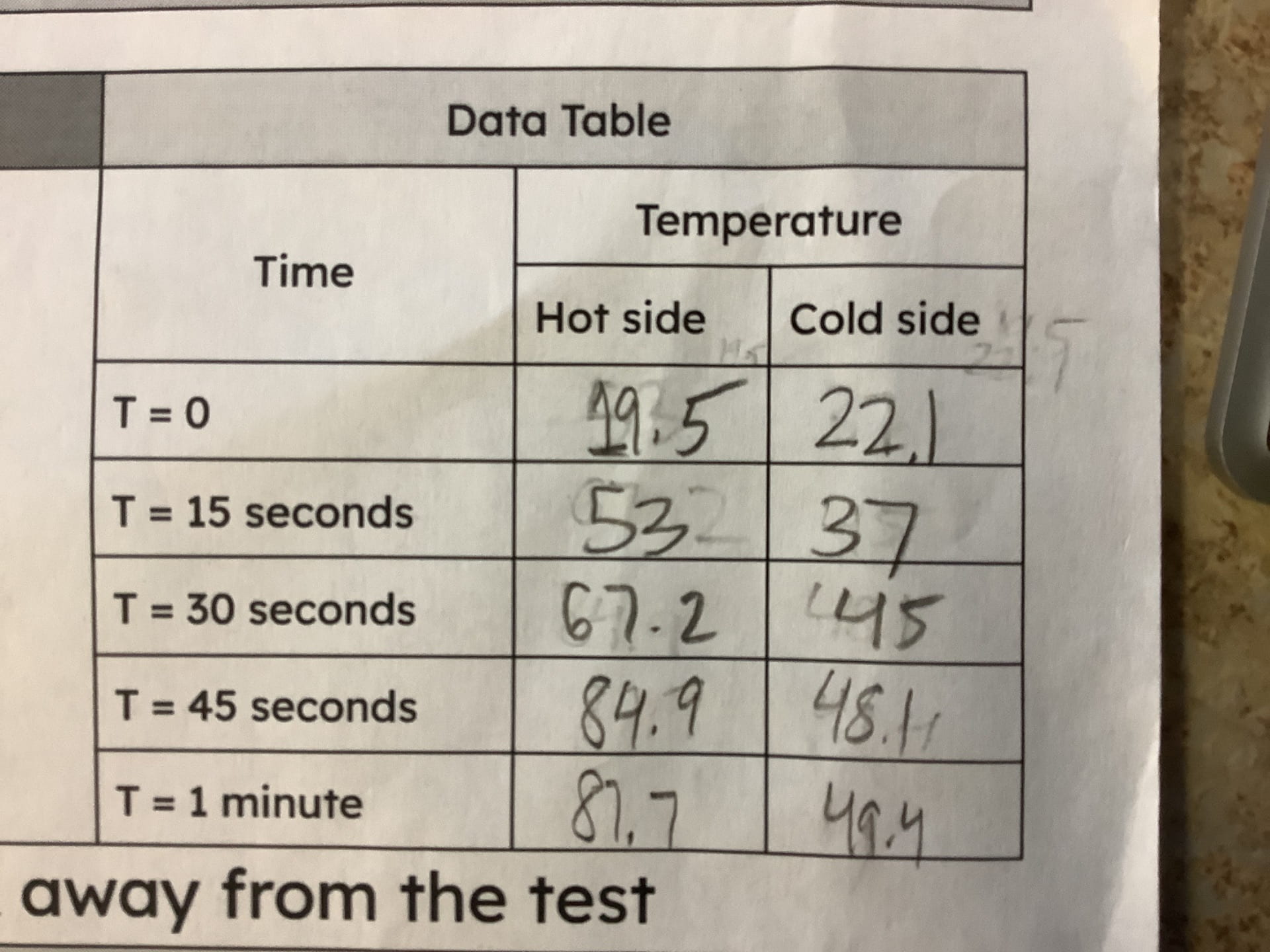

Are second test is about fining a good insulator. So we used a sponge and spackaling compound to make a good insulator.

As you can see the hot side of the insulator was very hot and that the cold side stayed ok.

Now that my group had found to good ideas to use we combined them to make are heat shield

Our heat shield is made of tin foil, metal lathe, lasagna, duck tape and a sponge. Our heat shield had to survive a blow torch.

I the end our heat shield survived and was the lightest so we won for our class.